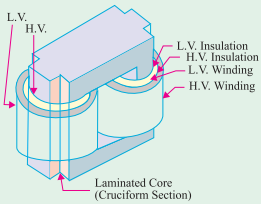

The eddy currents cause energy to be lost from the transformer as they heat up the core meaning that electrical energy is being wasted as unwanted heat energy.

Why must the core of a transformer be laminated.

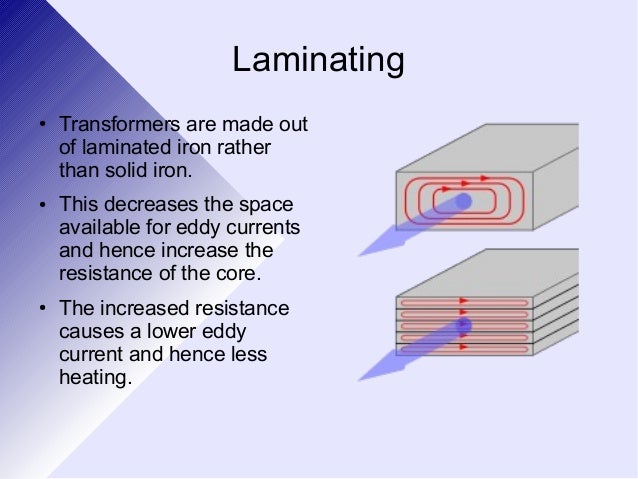

The reason we laminate the iron cores in transformers is because we want to limit what are called eddy currents.

The purpose of providing an iron core in a transformer is to.

But a solid iron core has some own disadvantage due to to some losses.

Eddy current is induced in core and circulates normal to the width of the core causing heat.

Reduce eddy current losses.

A new location or just.

For this reason electrically isolated laminations are utilized to manufacture transformers.

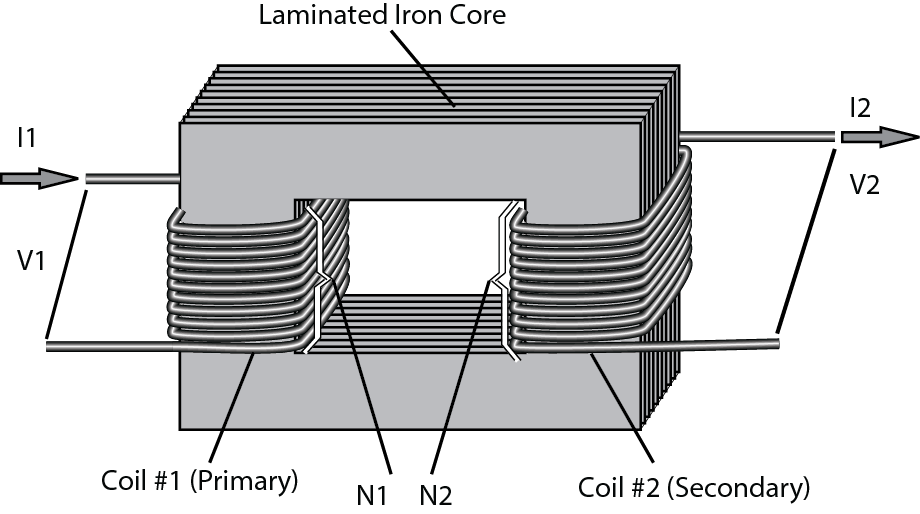

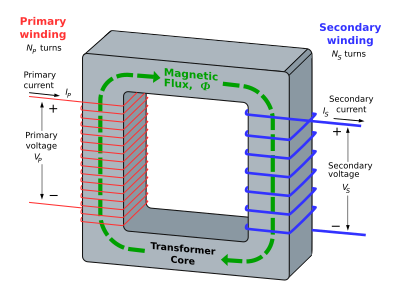

Transformers are basically two coils of wire wrapped around a core of iron.

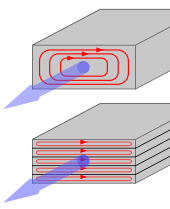

The figure below displays side view of transformer core where the eddy current flow in a solid and laminated core is indicated with red colored lines.

Why iron core is thin laminated in transformer.

The core is laminated to reduce these to a minimum as they interfere with the efficient transfer of energy from the primary coil to the secondary one.

The iron core transformer has higher permeability thus it is applied in transformer in place of air core in modern transformer.

Laminated magnetic core reduces eddy currents.

In a power amplifier this not only wastes power and limits operation with batteries but increases operating costs and requires higher rated output devices.

A maximum theoretical efficiency of 25 is obtainable using usual configurations but 50 is the maximum for a transformer or inductively coupled configuration.

They work by induction.